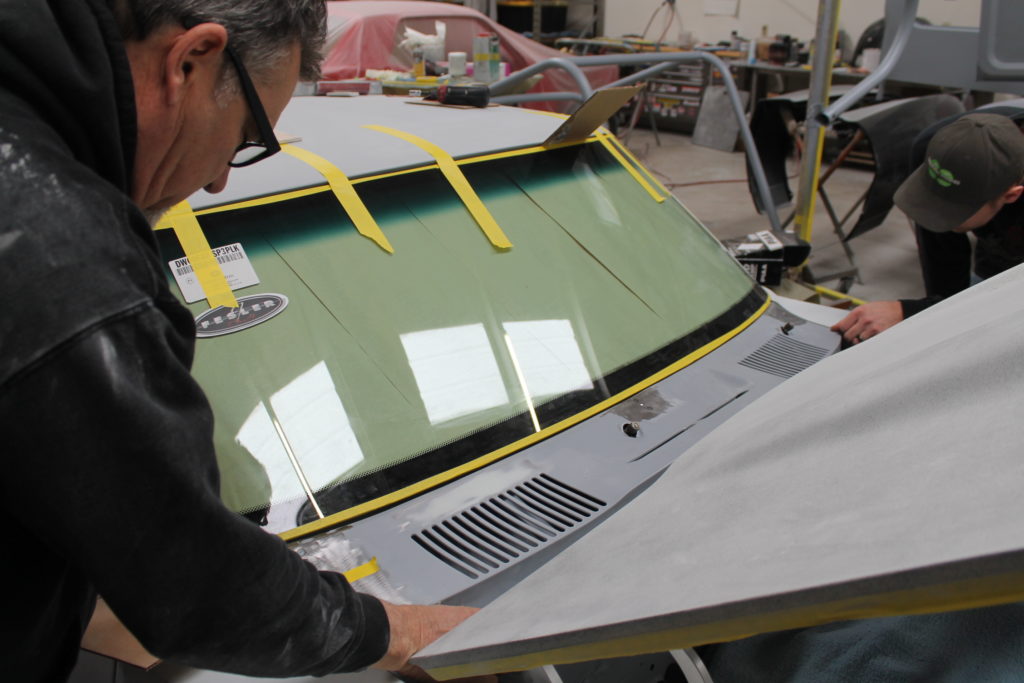

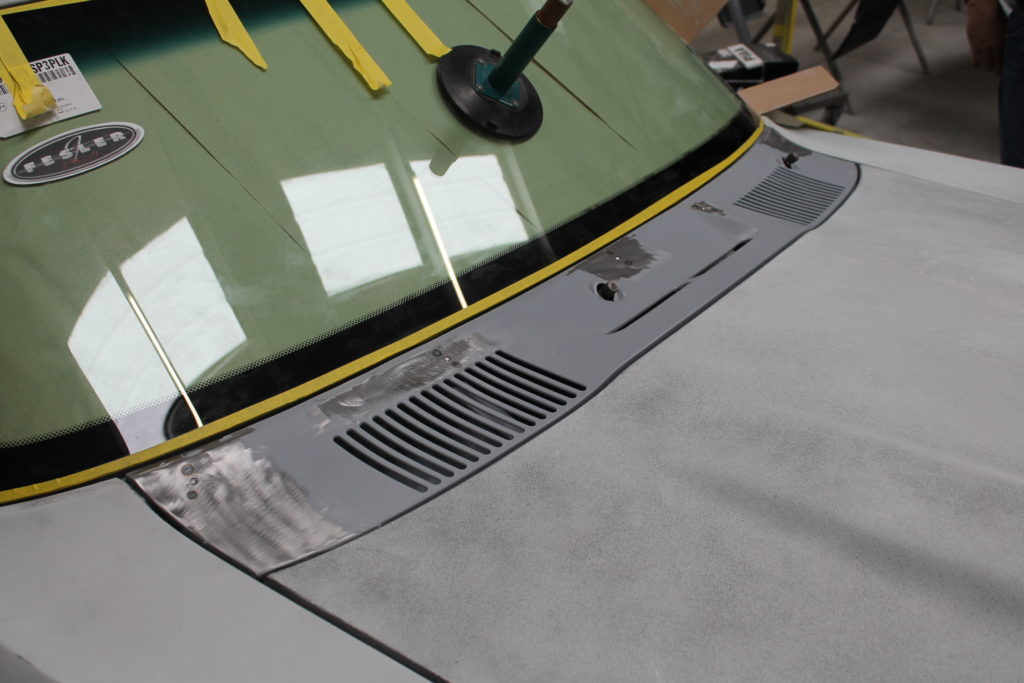

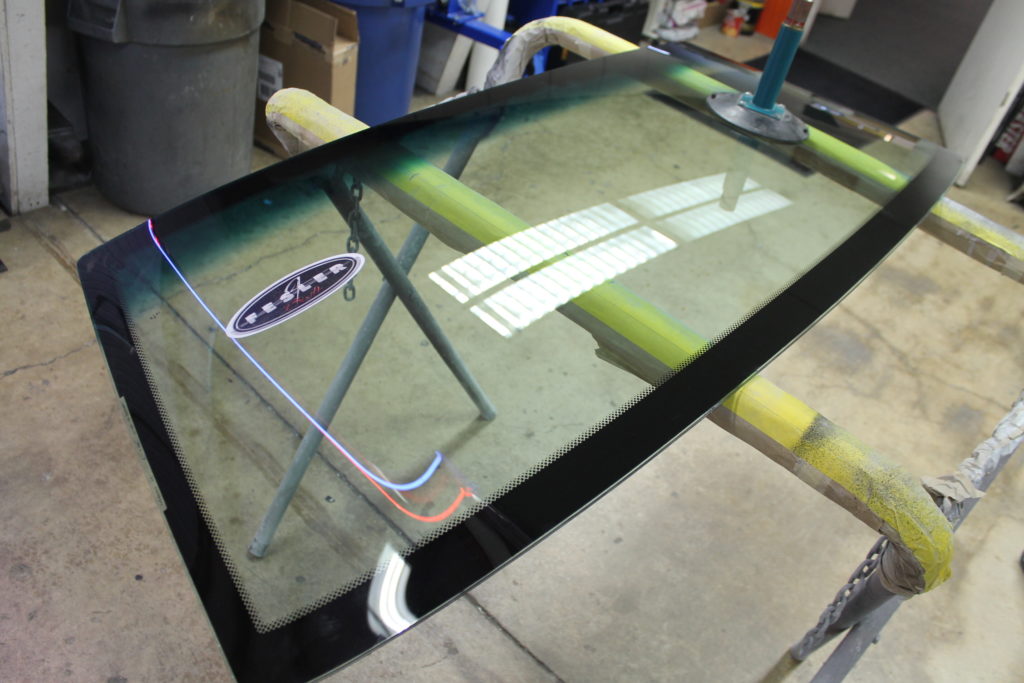

Fesler flush mount glass in a 1968 Firebird

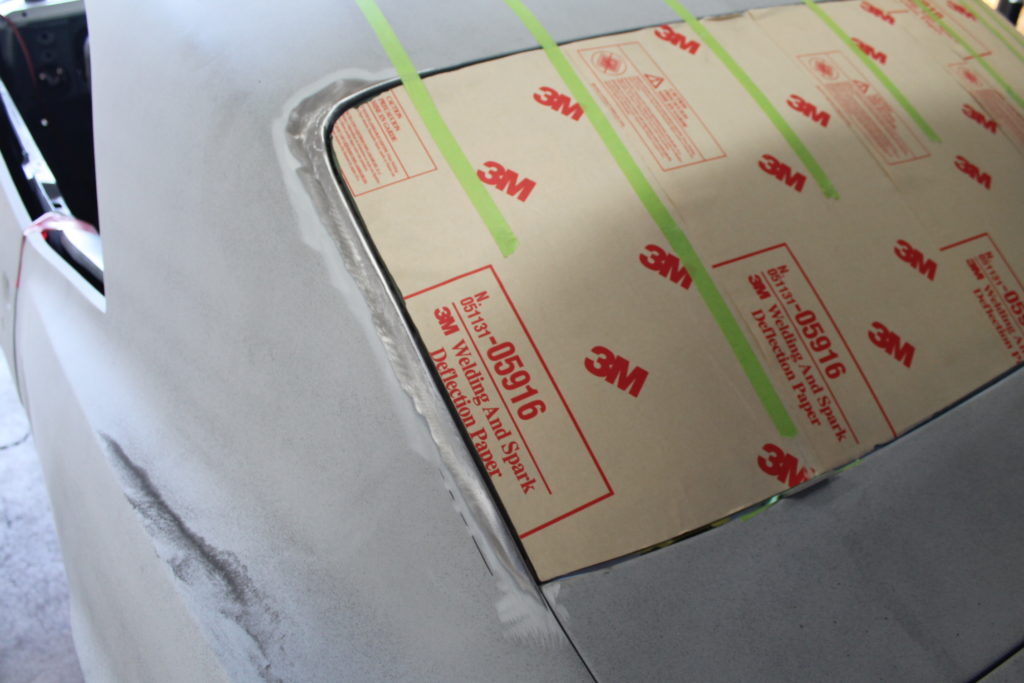

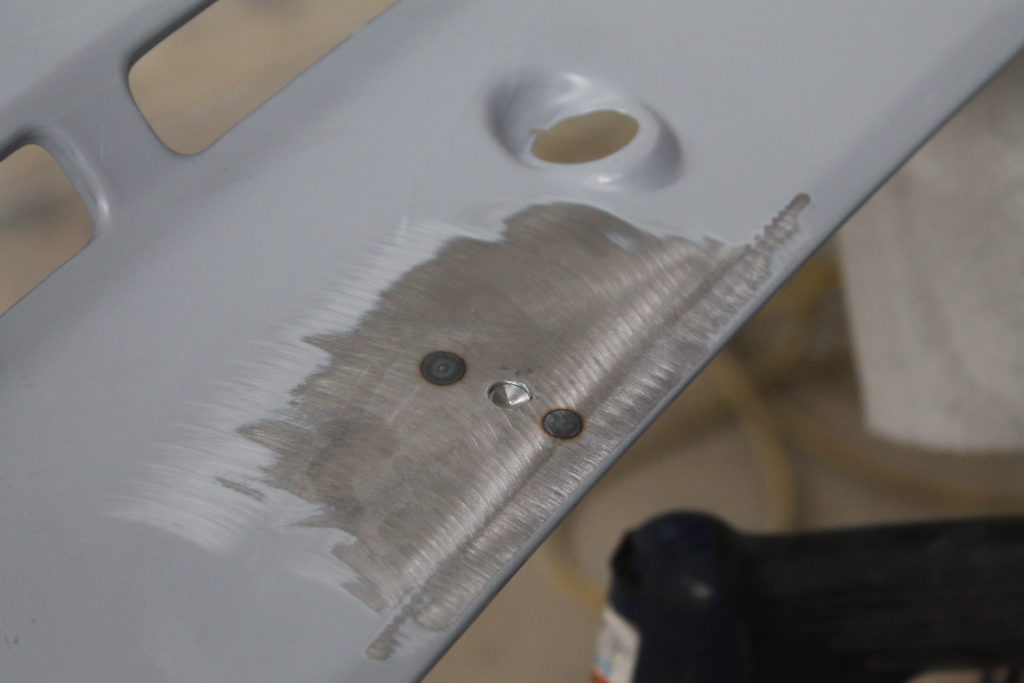

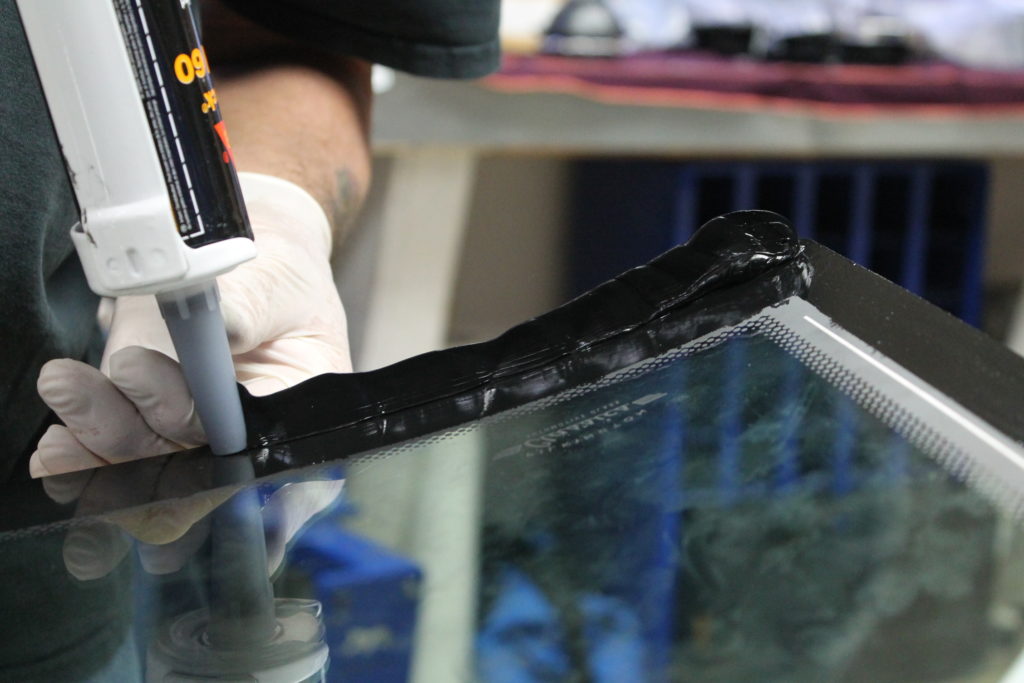

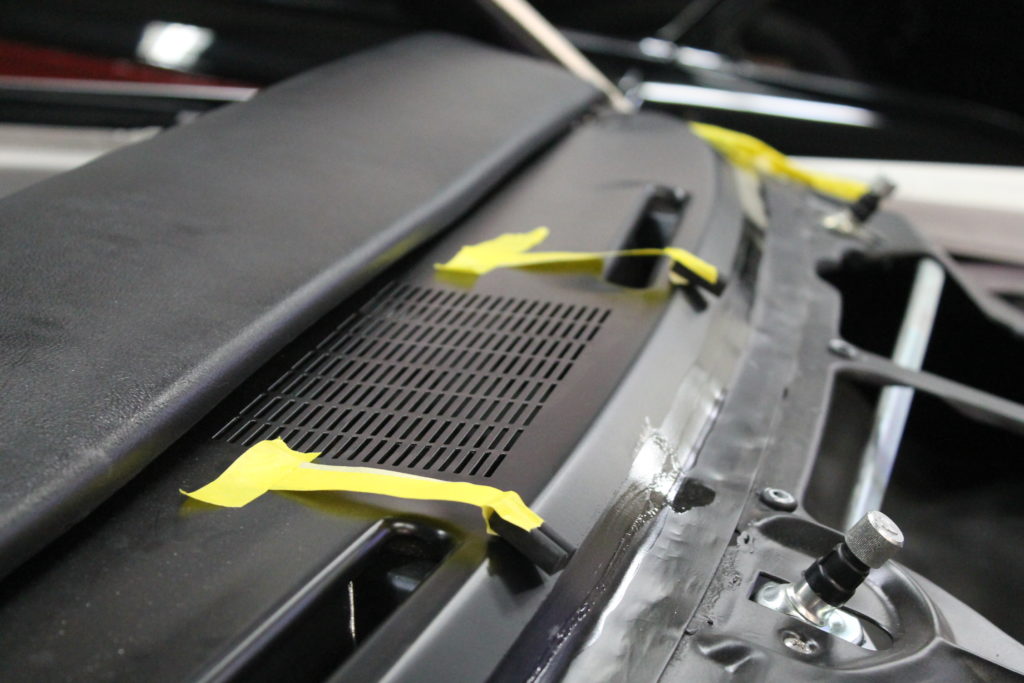

Flush mounted glass is a great way to give your classic car a sleek and modern look, but it does come with a fair amount of work. You need to factor in that classic cars were never designed for flush glass, so the factory openings will need to be reworked to accommodate for the new glass. Factory glass was accented with trim pieces that hid components like window clips, and seals…these components will no longer apply, so you will need to “build” the car around the glass. Let’s take a look at how the crew at MetalWorks Classic Auto Restoration tackled installing Fesler’s new flush glass in their 1968 Firebird build.